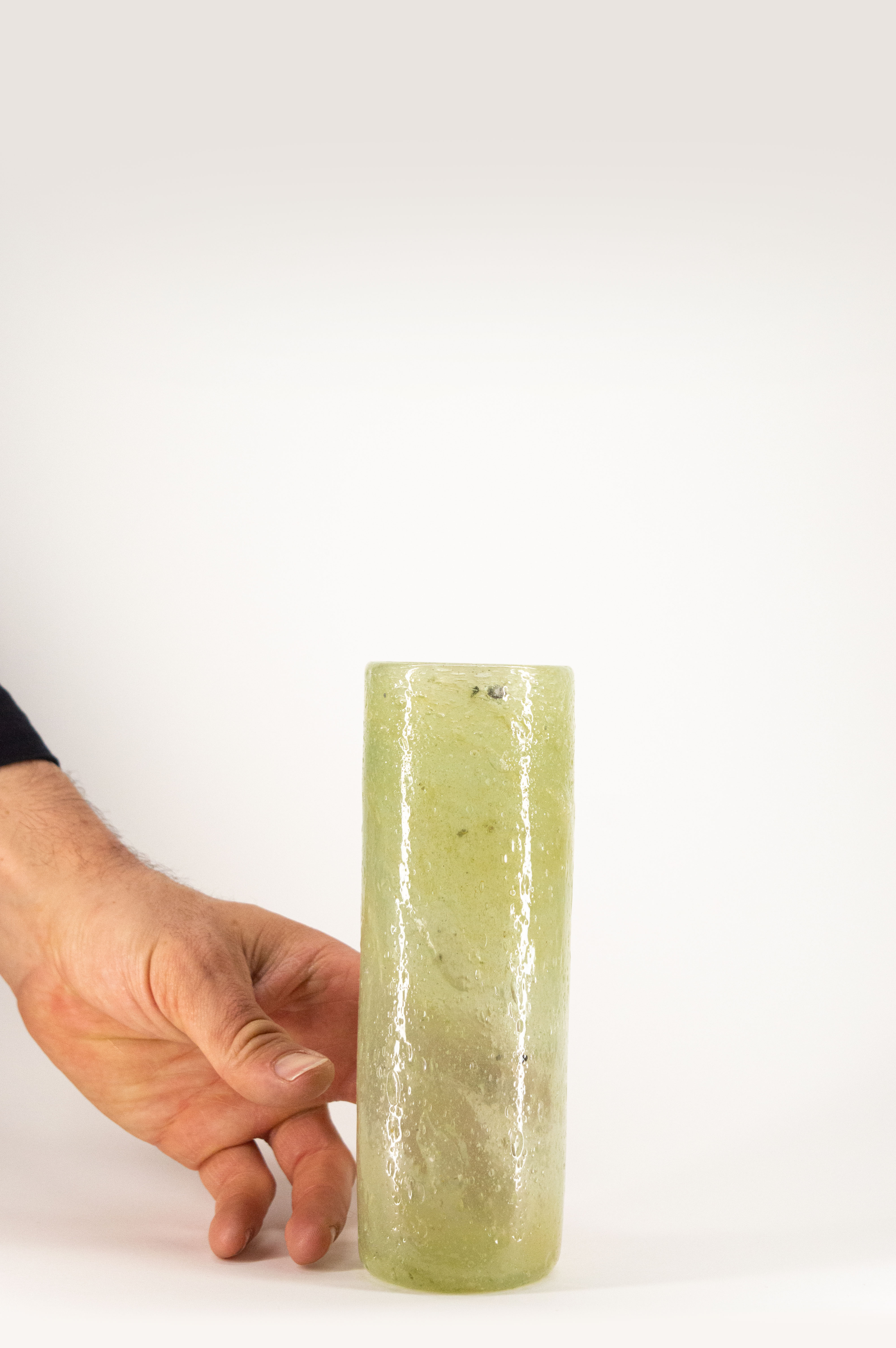

From the ashes

︎︎︎ A glass for next generations

The realisation of the glass into objects is done in close cooperation with glassblower theglassapprentice.com

Glass is often seen as sustainable, because it can be recycled endlessly and it is one of the few materials where it works almost worldwide. But if you look closer, it's not that easy. In addition to a high level of hidden energy, various ingredients are required that are mostly problematic. This glass is a first step towards improvement.

![]()

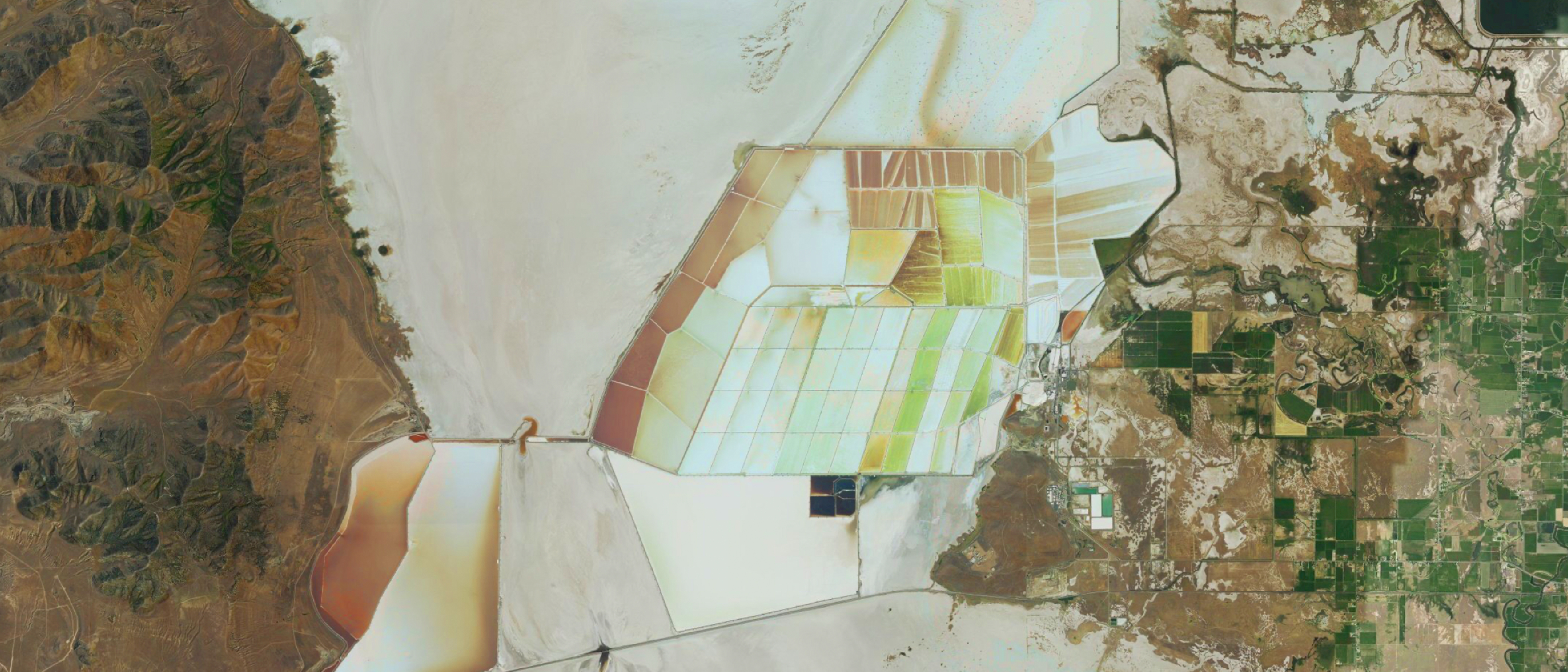

In addition to sand, glass usually requires two other main components: Sodium Carbonate and Calcium Carbonate. As with most industrial processes, the availability of these ingredients is changing dramatically due to climate change and human production methods.

Sodium Carbonate as a flux lowers the melting point by about 250° C. After extraction in salt lakes, it is manufactured using the Solvay process, which requires a high level of water and energy as well as quicklime: Rare limestone heated to 1000° C.

Energy consumption that is completely overlooked in the case of glass.

Great Salt Lake, Utah, USA | Biggest salt lake in the western hemisphere | 41.294750°, -112.258444° (source: google maps)

Great Salt Lake, Utah, USA | Biggest salt lake in the western hemisphere | 41.294750°, -112.258444° (source: google maps)

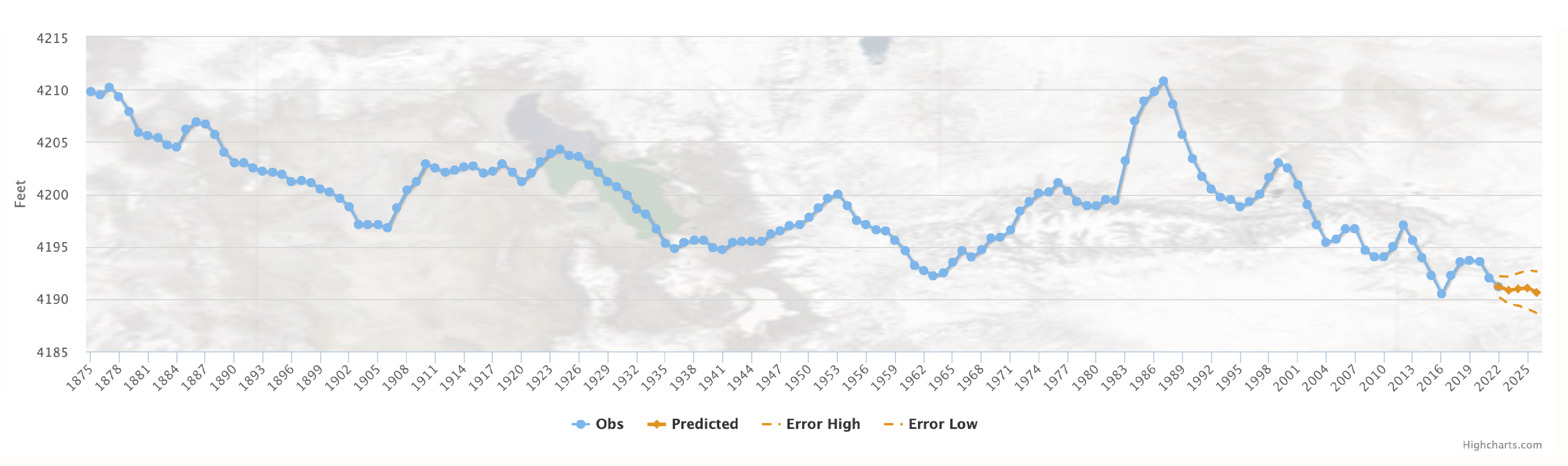

Great Salt Lake Annual Level Prediction, Utah Climate Center

Limestone is removed in large mines to get Calcium Carbonate. The material is used in all possible areas of our everyday life, but it is limited. Limestone was formed over hundreds of millions of years and there is an annual usage of 5000 million tons of limestone.

The largest mine in Europe will be exhausted in 2048.

Limestone mine, Wülfrath, Germany | Largest limestone mine in EU | 52.481147°, 13.80039° (source: google maps)

Limestone mine, Wülfrath, Germany | Largest limestone mine in EU | 52.481147°, 13.80039° (source: google maps)︎︎︎ from the ashes discovers infinite supply chains by using waste which has no value so far: Ashes from wood-fired pizzerias and sea shells from seafood restaurants. These renewable raw materials are locally available worldwide. No continental transport is necessary, no external exploitation, no environmental destruction.

The preparation of the ingredients requires no chemical additives. The recipe, which has been balanced over several years, also uses significantly less energy than ordinary productions.

Two out of three ingredients are recycled waste.

No continental transport, no external exploitation, no environmental degradation.

No continental transport, no external exploitation, no environmental degradation.

Potassium carbonate can be extracted from wood ash. A forgotten flux that was used in previous years. Many pizzerias produce wood ash as a by-product that can be processed with simple steps. Seashells consist largely of calcium carbonate and once formed some of the limestones. Finely ground they give glass the well-known durability and they, too, accumulate in large quantities as waste.

The increasingly scarce material quartz sand has not yet been replaced. In contrast to concrete and other high consumers, glass can be recycled endlessly. It can even be ground to sand again, which means that the material is in a closed cycle if the additives are harmless. Unfortunately, many glasses are not.

from the ashes is a 100% natural glass, free of toxic or limited additives and made for next generations.

The studio is constantly looking for ways to recycle the third ingredient, quartz sand, from another process. For glass, however, its quality and purity must be extremely high. The sand currently used comes from a nearby German quarry.

The studio is constantly looking for ways to recycle the third ingredient, quartz sand, from another process. For glass, however, its quality and purity must be extremely high. The sand currently used comes from a nearby German quarry.

These patterns are created by an extremely short and energy-saving melt.

The very first results. Various recipes and ingredients were compared in these test bowls. For example, a whole range of different ashes and sea shells.

The very first results. Various recipes and ingredients were compared in these test bowls. For example, a whole range of different ashes and sea shells. The different stages of the melt, the longer the more transparent and homogeneous.

The different stages of the melt, the longer the more transparent and homogeneous.